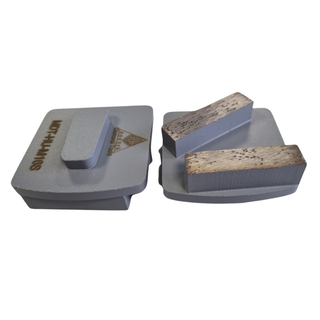

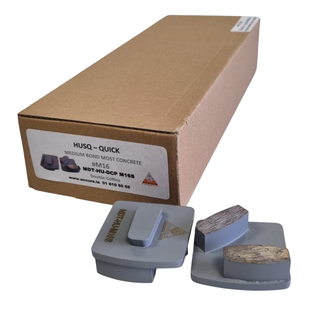

Product includes a box of NINE (9) segments. - MEDIUM BOND

Available in 16, 30, 60, 100 & 200 Grit.

AccurA Diamond Tools diamond tooling is engineered to meet the specific demands of grinding, polishing, and coating removal. While all diamond tools use industrial-grade diamonds, the manufacturing process varies depending on the bond type—metal-bond, resin-bond, or PCD—so that each tool performs optimally for its intended application.

The metal component of the bond delivers strong cutting ability and long life, while the resin component cushions the diamond for a smoother scratch pattern and improved surface finish. This combination allows hybrid resin tooling to transition easily between aggressive stock removal and fine polishing, often reducing the number of steps in a process.

Standard Applications

- Concrete surface preparation – transitioning from metal grinding to resin polishing

- Terrazzo – levelling and refining surfaces before final polishing

- Natural stone – honing granite, marble, and other hard surfaces without chipping

- Coating removal – when a smoother finish is desired after stripping sealers or adhesives

Key Advantages

- Faster workflow by bridging the gap between metal and resin stages

- Longer life compared to standard resin pads

- Consistent, high-quality finish

- Reduced tool changes and downtime

Accura Diamond Tool's diamond tools are especially valuable in floor polishing and restoration projects where efficiency and finish quality are both critical. They are commonly used by contractors, fabricators, and restoration specialists who need reliable results across different materials and job conditions.

For further information contact us today. 01 610 50 55

Ireland wide next day delivery

Longer lifespan with industrial diamond segments

Call us for product advice

You may also like

Product includes a box of NINE (9) segments. - MEDIUM BOND

Available in 16, 30, 60, 100 & 200 Grit.

AccurA Diamond Tools diamond tooling is engineered to meet the specific demands of grinding, polishing, and coating removal. While all diamond tools use industrial-grade diamonds, the manufacturing process varies depending on the bond type—metal-bond, resin-bond, or PCD—so that each tool performs optimally for its intended application.

The metal component of the bond delivers strong cutting ability and long life, while the resin component cushions the diamond for a smoother scratch pattern and improved surface finish. This combination allows hybrid resin tooling to transition easily between aggressive stock removal and fine polishing, often reducing the number of steps in a process.

Standard Applications

- Concrete surface preparation – transitioning from metal grinding to resin polishing

- Terrazzo – levelling and refining surfaces before final polishing

- Natural stone – honing granite, marble, and other hard surfaces without chipping

- Coating removal – when a smoother finish is desired after stripping sealers or adhesives

Key Advantages

- Faster workflow by bridging the gap between metal and resin stages

- Longer life compared to standard resin pads

- Consistent, high-quality finish

- Reduced tool changes and downtime

Accura Diamond Tool's diamond tools are especially valuable in floor polishing and restoration projects where efficiency and finish quality are both critical. They are commonly used by contractors, fabricators, and restoration specialists who need reliable results across different materials and job conditions.

For further information contact us today. 01 610 50 55

Ireland wide next day delivery

Longer lifespan with industrial diamond segments

Call us for product advice

You may also like

Top 10 FAQ Suggestions for Accura Diamond Tools

Limited Stock Remaining – Order Now!